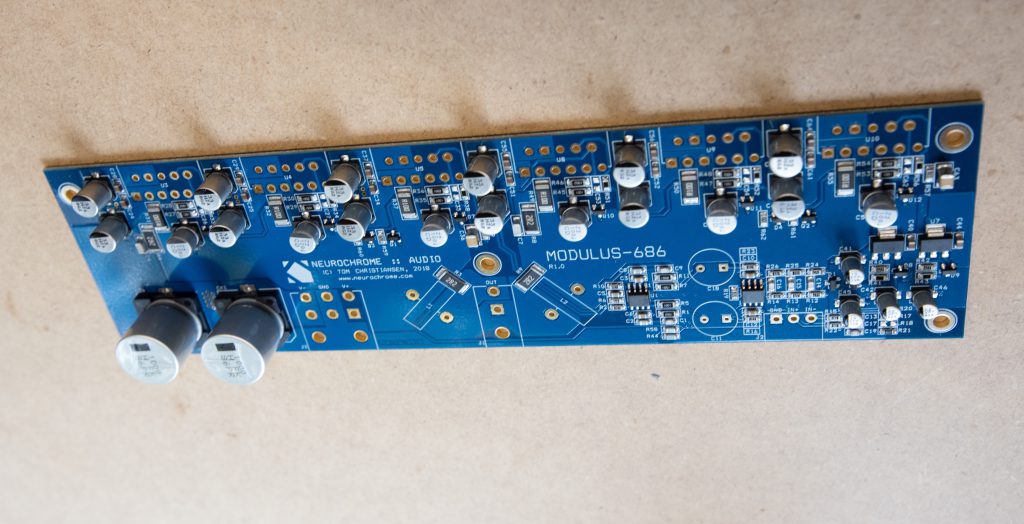

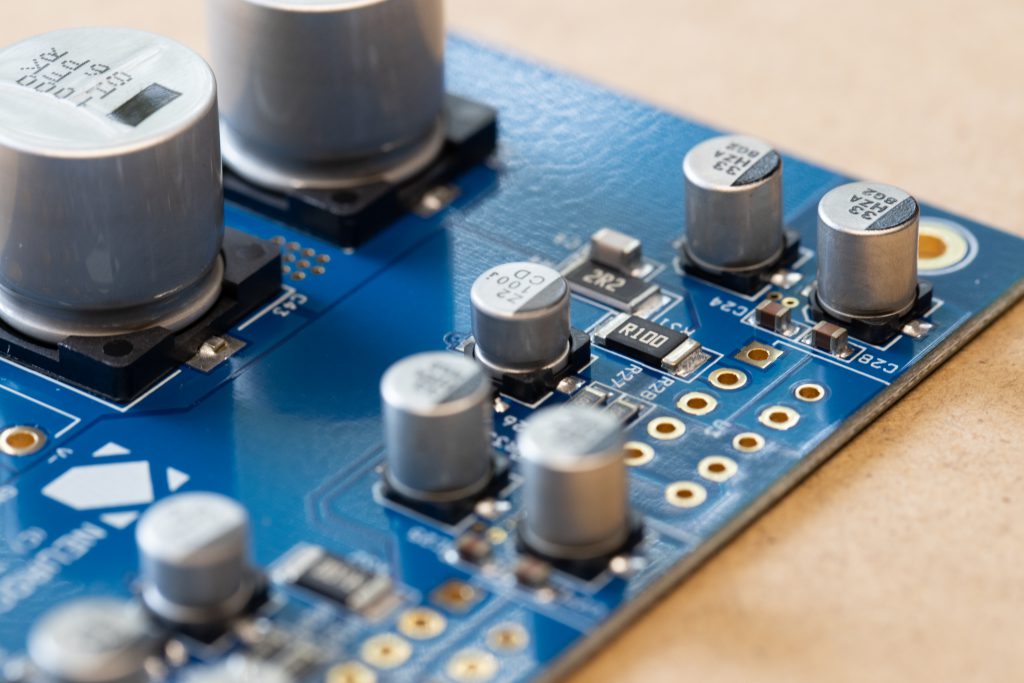

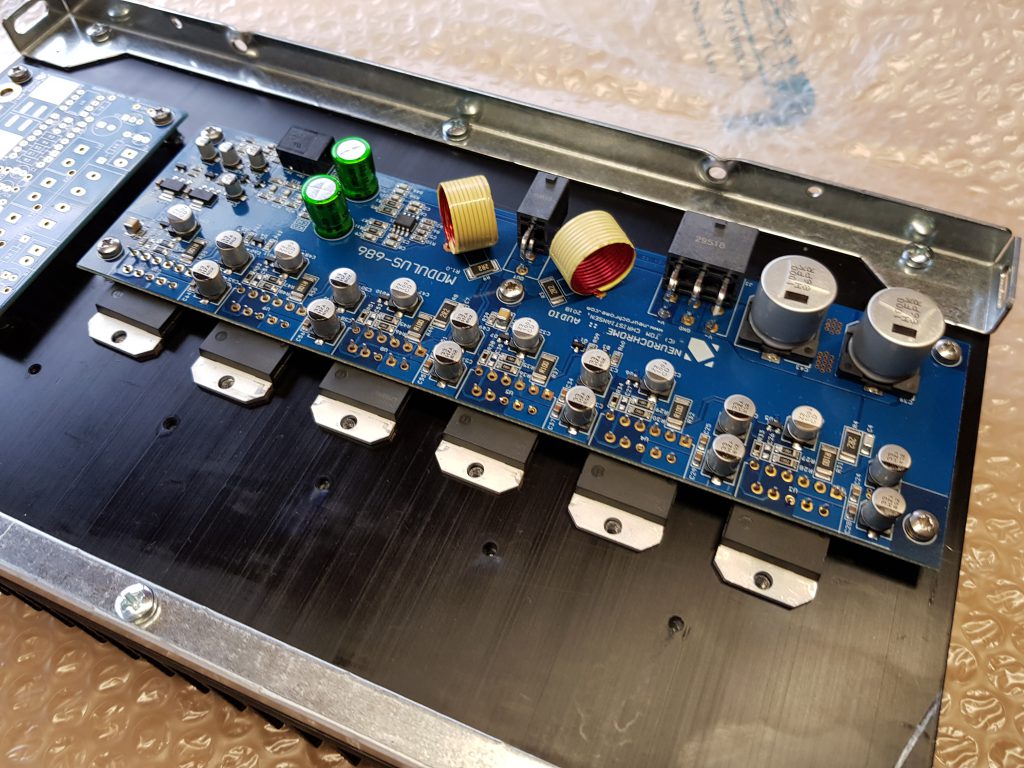

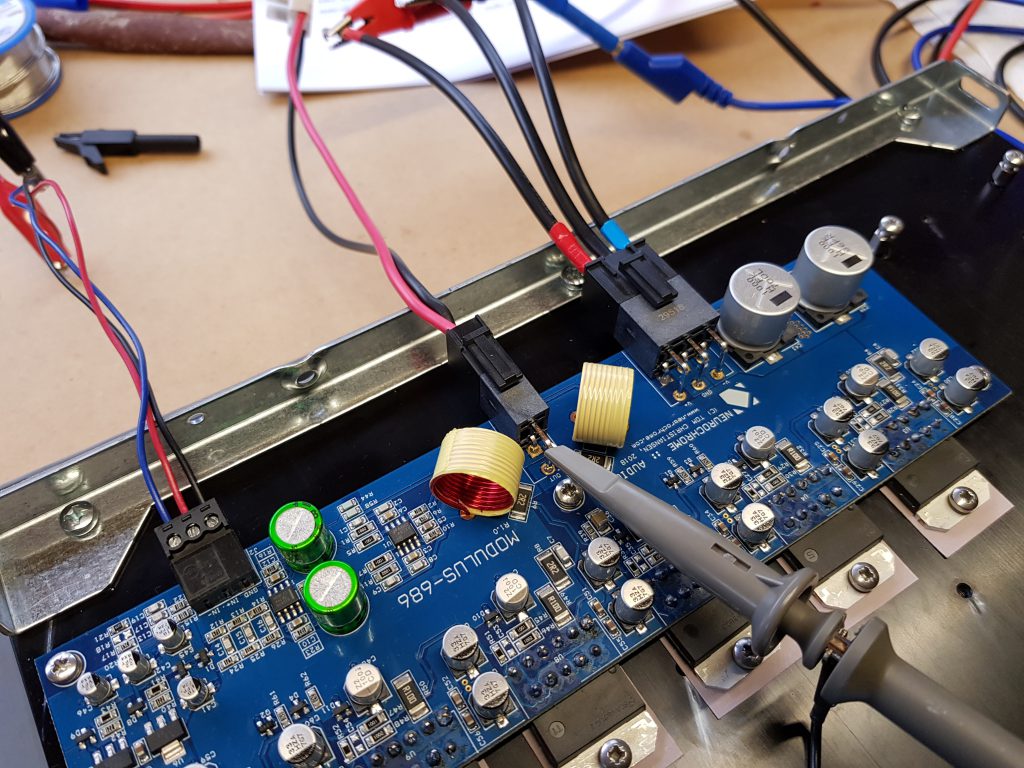

Modulus Board pre-populated with SMD components. This is so we can change the way we mount the LM3886 chips.

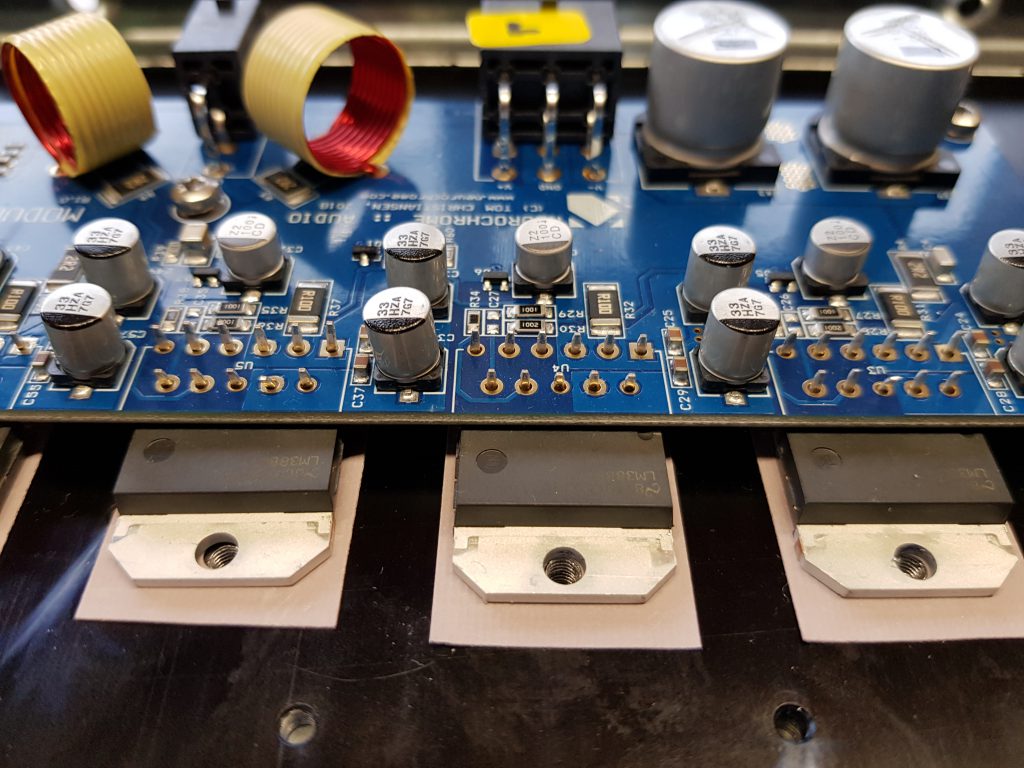

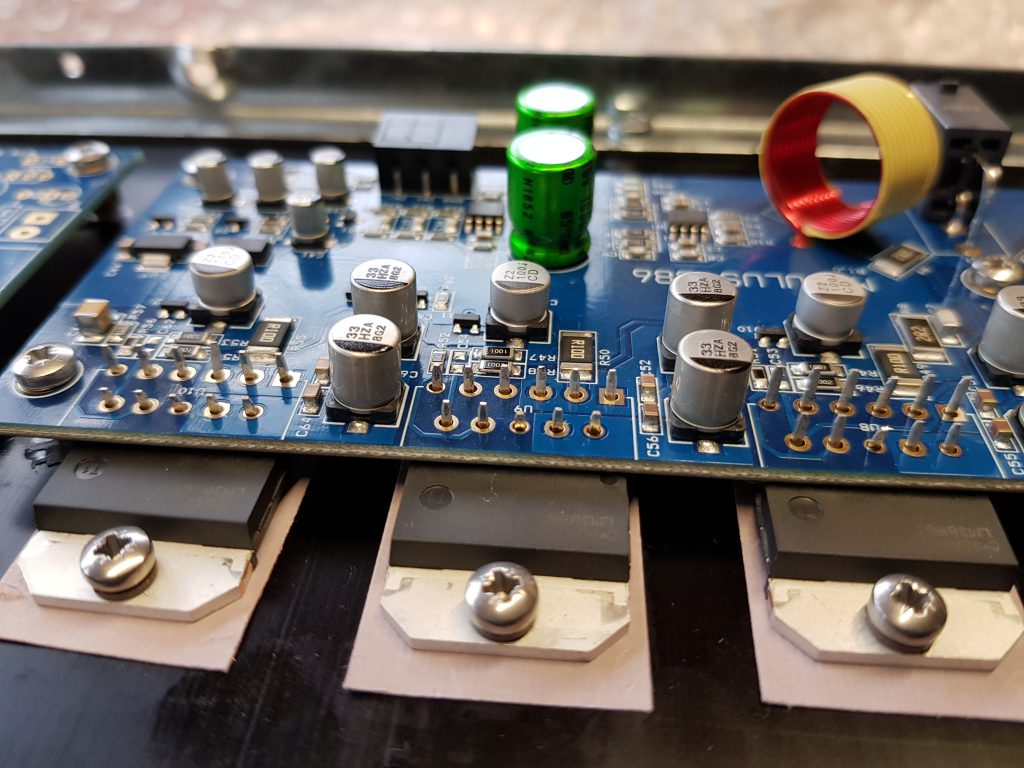

The heat sinks that come with the Deluxe modushop chassis are pre-drilled to their own spec which meets the needs of many a DIY project, but not this one. Only two of the holes match one board so the others have to be drilled and tapped. This is made easier with some cutting fluid. Without the fluid a number of the taps ended in failure, and epoxy glue had to be used for the standoff.

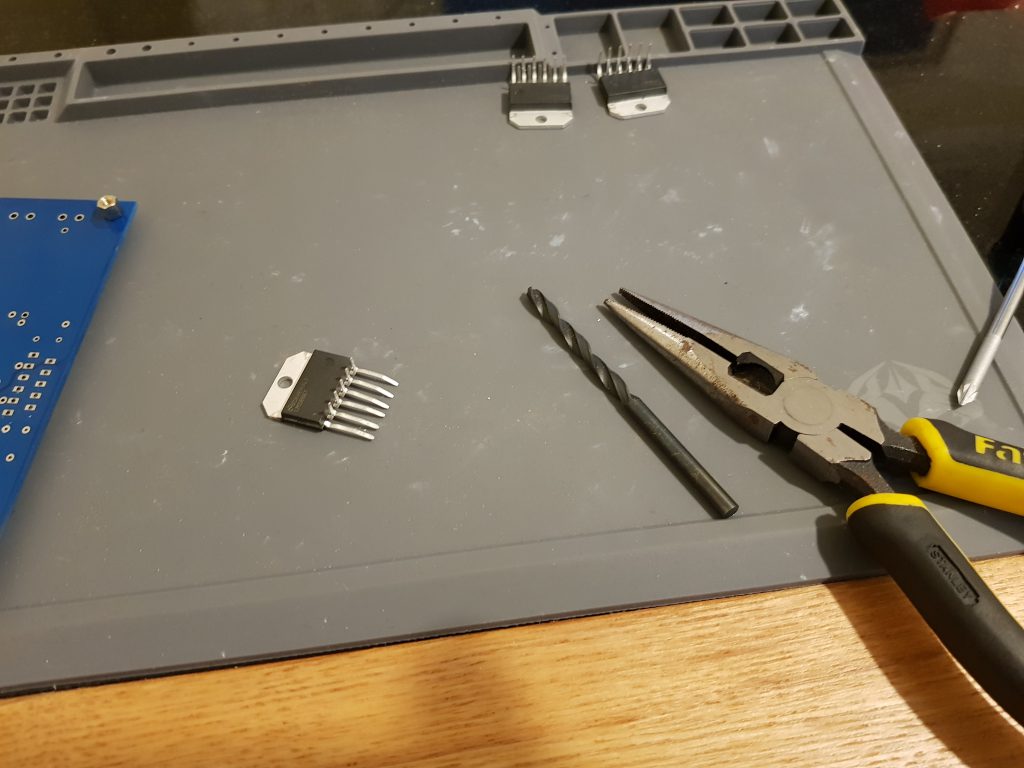

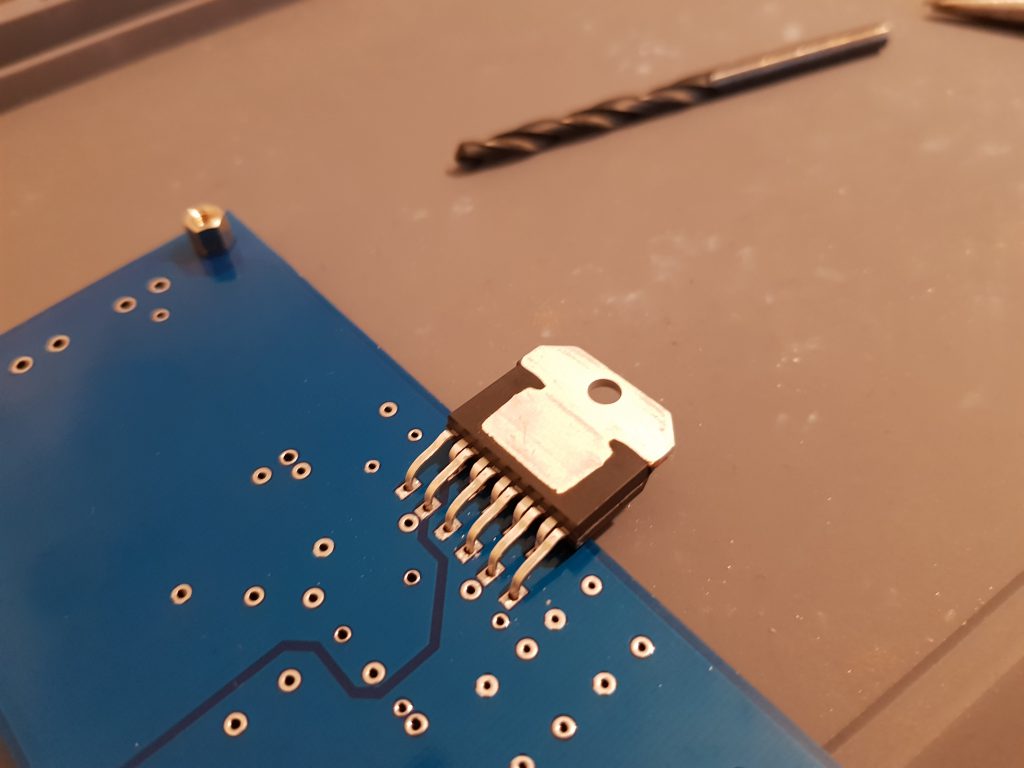

Since the LM3886 chips are to be mounted in reverse the first task is to straighten the legs. Then roll the first row around a slim drill bit to keep the bend away from the casing. Finally roll around a thicker drill bit to bend the second row. Used a spare PCB board (from another project) with an LM3886 socket to make sure legs are aligned.

Drill bit idea came from builders in the diyAudio.com threads.

Thermal pads much better than wearing thermal paste again.

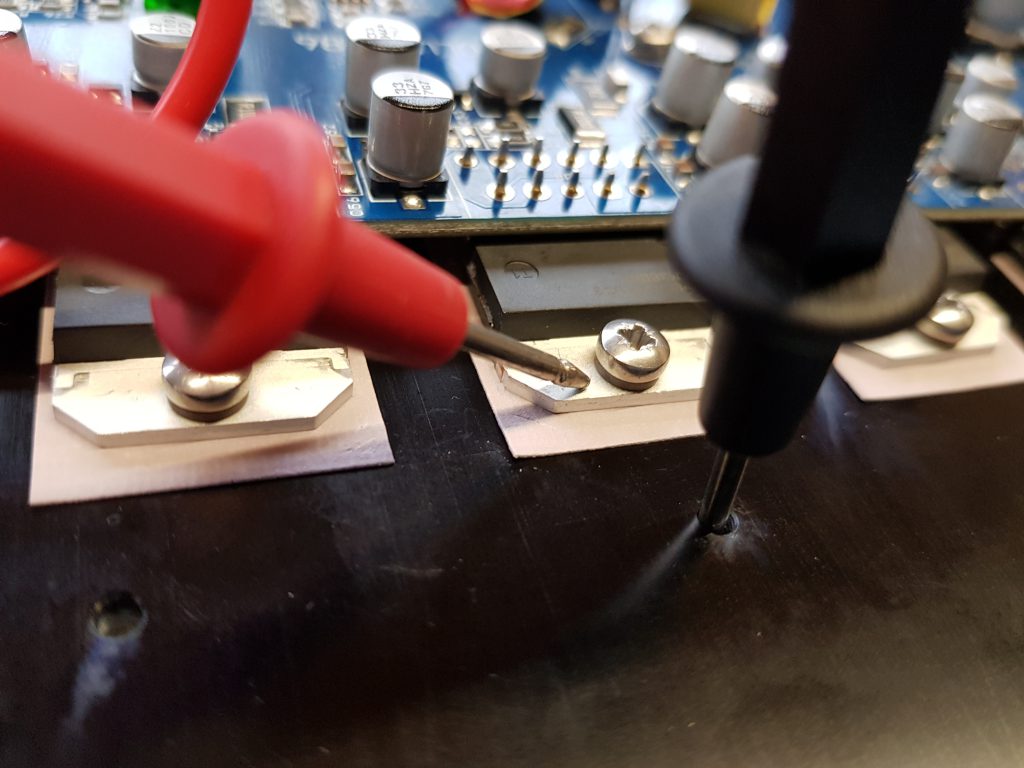

A quick continuity test to make sure the LM3886 metal back plate is isolated from the heat sink and screw via plastic shoulder. Otherwise the chassis becomes -V and that would be bad!

A quick bench test with a bench power supply limiting the current. Input from a frequency generator 400hz, sent to some 4 Ohmn car speakers for testing. Audio is heard correctly.